More tan 100 years innovating in industrial ventilation

More tan 100 years innovating in industrial ventilation

Industrial ventilation

Since 1920 CIRIGLIANO has constantly pursued the continuous improvement from the design to the final production.

Its production plant, located in the city of Junín, has the following areas: administration, die-stamping, fan testing laboratory, model factory, bronze and aluminum die-casting, design room, gray cast iron, electric motor factory, assembly and offices.

In each of them there is a rigorous quality control, achieving highly efficient products and services. Continuous development, initiative, experience and constant improvement is what makes CIRIGLIANO an Argentine industry leader in manufacturing axial, helical, centrifugal and mixed flow fans.

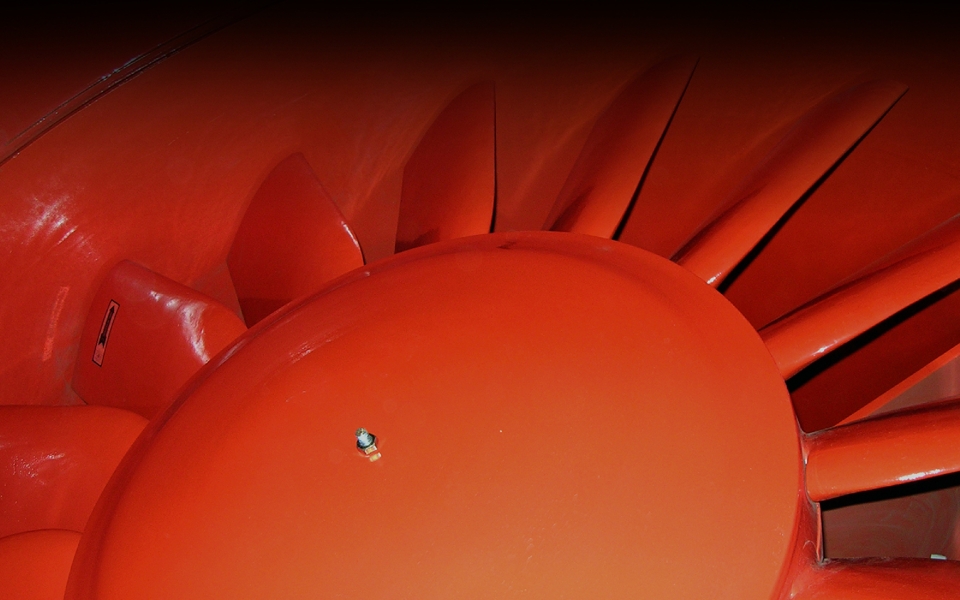

Centrifugal Fans

Applications and requirements

Air conditioning and ventilation: We seek good efficiency, to obtain low operating costs, operation and low noise level. Its good design ensures long life with minimal maintenance.

Pneumatic transfer: Material handling, loading and unloading services. Venturi system.

Smoke extraction: Handling of acids or other corrosive fumes. Where your service requires it, they can be made of stainless steel.

Forced type: It is generally used for combustion systems, with solid, liquid, or gaseous fuels. They ensure maximum efficiency in continuous operating conditions.

Induced draft: Any type of demand.

Agriculture: An interesting area of application. For this market we not only manufacture standard fans, but also others suitable for integration into this type of machinery.

Dust handling: Visiting farms, factories and quarries in the country, you will be able to find our fans. Whether dust is removed from a process due to contamination hazards, or reclaimed for any reason, our experience will enable you to select the most appropriate fan. Our fans allow the blades to be placed at any angle to give the volume required by the customer in manufacturing.

Drying systems: In our records we have references to various drying systems (automotive products, coffee, tobacco, paint, fertilizers, grains, etc.).

Gas pumping: Strict controls are carried out to verify its tightness.

Refrigeration: We pay special attention to the humidity conditions in which the fan works, protecting it with special paints or building it entirely in fiberglass-reinforced polyester.

Air treatment units: We manufacture these units, and also fans adaptable to other equipment.

Spray booths: Many systems require access for daily cleaning and maintenance, so fan selection must take into account its mounting location.

Hot gas systems: Many of the fans described may be suitable for high operating temperatures. For not very high thermal levels, common insulated shafts and bearings are used, which minimize gas losses. For higher levels, special compatible bearings are used for safe operation and ease of maintenance.

28 SERIES

• SASE (SINGLE WIDTH - SINGLE ENTRY)

•DADE (DOUBLE WIDTH - DOUBLE ENTRY)

• 23 STANDARD DIAMETER

• 7 TYPES OF BLADES

• 2 WIDTH

• LOW NOISE LEVELS

• HIGH EFFICIENCIES

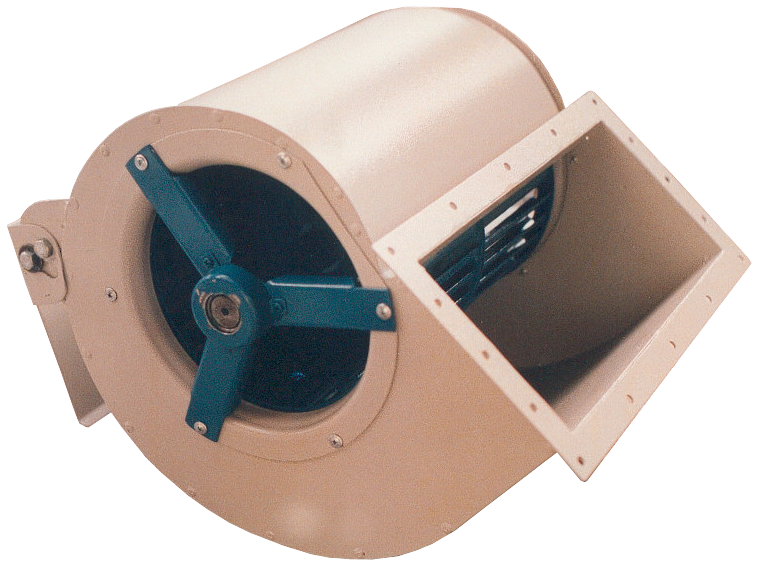

PC23

• BLOWERS AND VACUUM CLEANERS

• 4 DIFFERENT DIAMETERS

• 3 TYPES OF BLADES

• 2 WIDTH

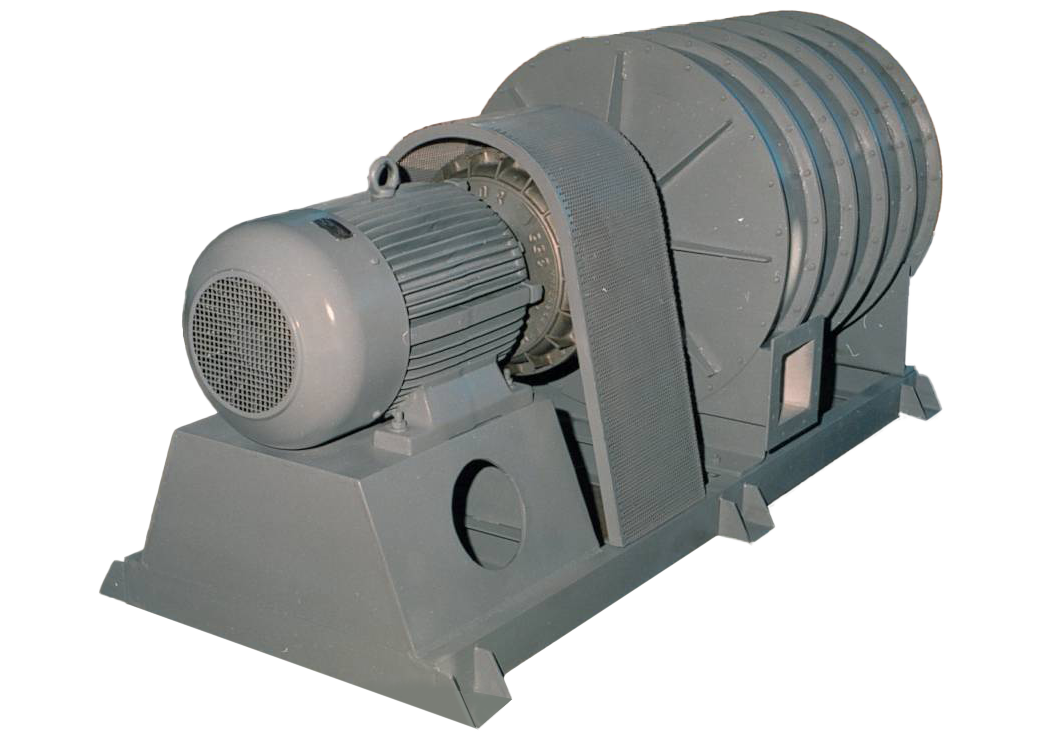

TSME

• MULTI-STAGE TURBOBLOWERS.

• THEY DEVELOP HIGH MANOMETRIC AND VACUUM PRESSURES.

• THEY ARE MANUFACTURED FROM 2 TO 7 STAGES IN SIZES FROM 350 TO 1000 MM.

FM 630

• SELF-CLEANING

• 3 TYPES OF BLADES

• 4 DOWNLOAD DIRECTIONS

CHIMEXTRA / GRILLS

• SMOKE EXTRACTORS FOR KITCHENS.

• MOUNTED DIRECTLY ON THE END OF 4 OR 6 INCHES DIAMETER PIPE.

.

• FLOW 860 M3/H.

• LARGER DIAMETERS, ASK.

MULTI-BLADE ROTORS

• FOR DRYING AND RECIRCULATION OVEN

• ROBUST CONSTRUCTION

• FINISH WITH BAKED POWDER PAINT SUITABLE FOR WORK IN THE GASTRONOMIC INDUSTRY