More than 100 years innovating in mine ventilation

More than 100 years innovating in mine ventilation

TUNNELS AND MINES

CIRIGLIANO manufactures single-stage and counter-rotating multi-stage axial fans for auxiliary underground mine ventilation and for tunnel drilling Works.

Its compact design requires little space allowing to hang it directly on the tunnel wall or to couple it directly to the duct. Multi-stages reduce the piping diameter.

Suction

Harmful gases are extracted from inside the mine through a chimney.

Blower

Fresh air is injected through a chimney and expelled through the intake ramp.

Main fans are used to move the total amount of air needed from inside the mine. They are robust and large equipment that move flows from 100,000m³/h to 750,000m³/h, usually at low RPM.

Auxiliary fans provide air inside the mine at remote sites. They are used to inject or extract air. They are small in size and easy to maneuver with flows from 10,000m³/h to 100,000m³/h and pressures up to 1000mm CA.

SINGLE STAGE FANS

Aerofoil fans for general purposes are of the type without rotating fin. The impeller rotates inside a cylindrical casing and is mounted directly on the drive motor shaft.

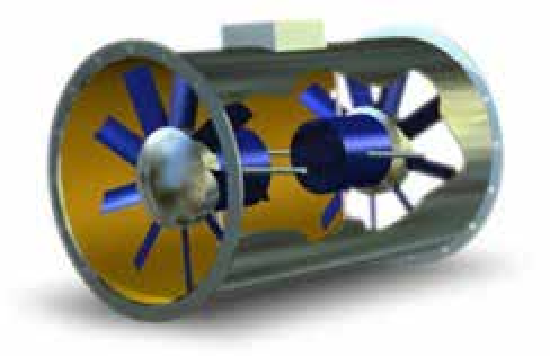

TWO-STAGE FANS

The use of contra-rotating units allows obtaining considerable pressures. This system, originally introduced by the Woods house, is now accepted worldwide and consists of 2 or more fans with blades of different orientation placed in series. The blades rotate in the opposite direction and are directly coupled to their corresponding motors.

FANS WITH GUIDING BLADES

Units with guide vanes placed on the discharge side of the fan allow to obtain average pressures between those produced by single-stage and two-stage contra-rotating units of identical diameter and speed.

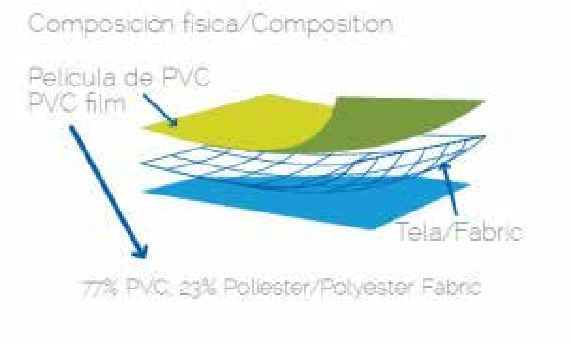

RIGID AND FLEXIBLE SLEEVES

Both blowing and suction ventilation ducts, in diameter

lengths from 300 to 1500mm, standard lengths 15 – 20 – 25 meters.

Reinforced construction for mining, made of anti-tear polyester fabric with double PVC layer.